K-packing

Thành viên

- Tham gia

- 17/10/2025

- Bài viết

- 6

When you choose a shopping bag supplier/manufacture, the decision affects far more than just the cost of your packaging. A reliable partner can strengthen your brand image, improve customer satisfaction, and keep your quality consistent across every order. On the other hand, a poor choice may lead to delays, hidden costs, quality issues, and unnecessary pressure on your team.

In this article, the 7 most common mistakes made during the supplier selection process are outlined, along with how avoiding them can bring long-term benefits to your brand, your operations, and your budget.

Table of Contents

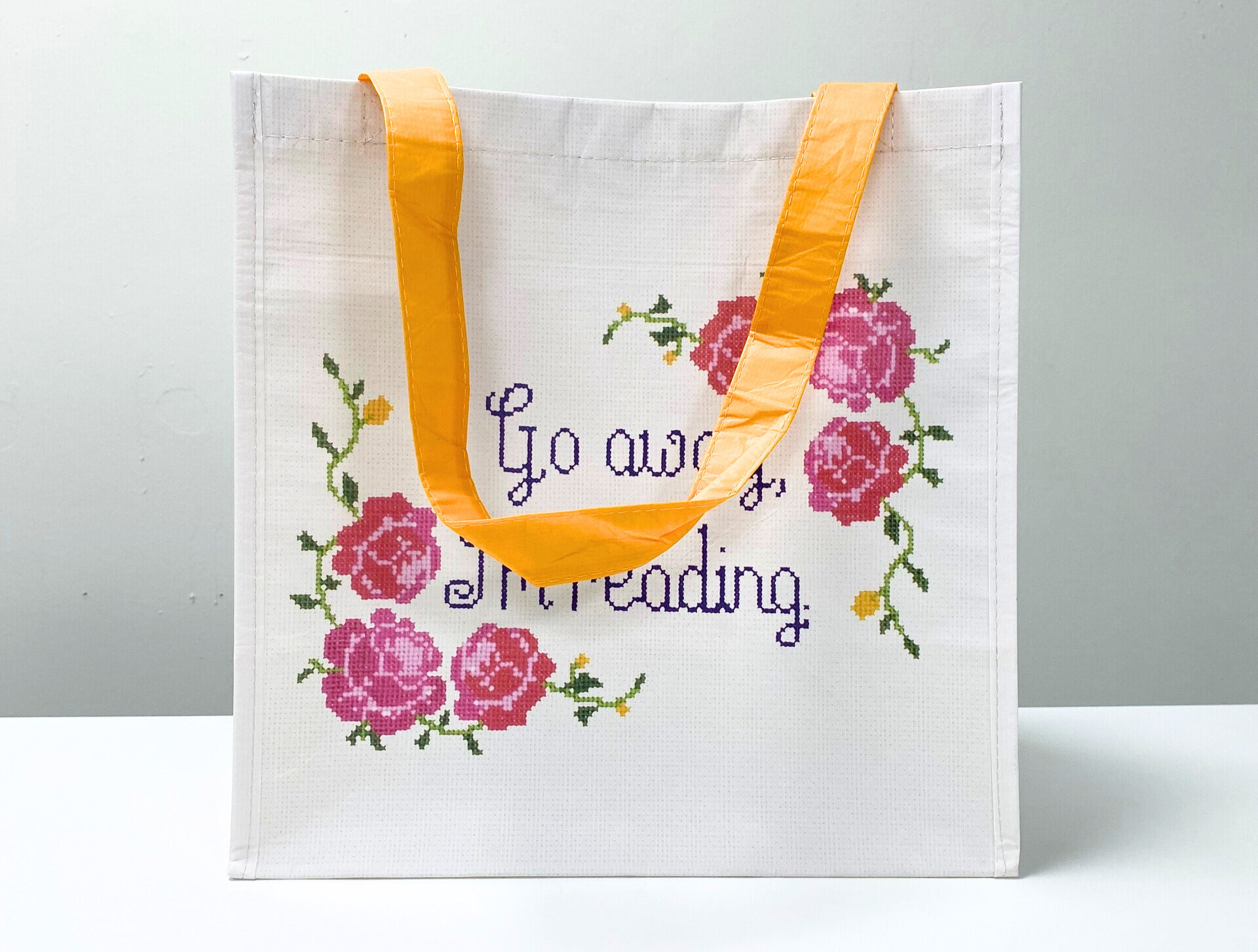

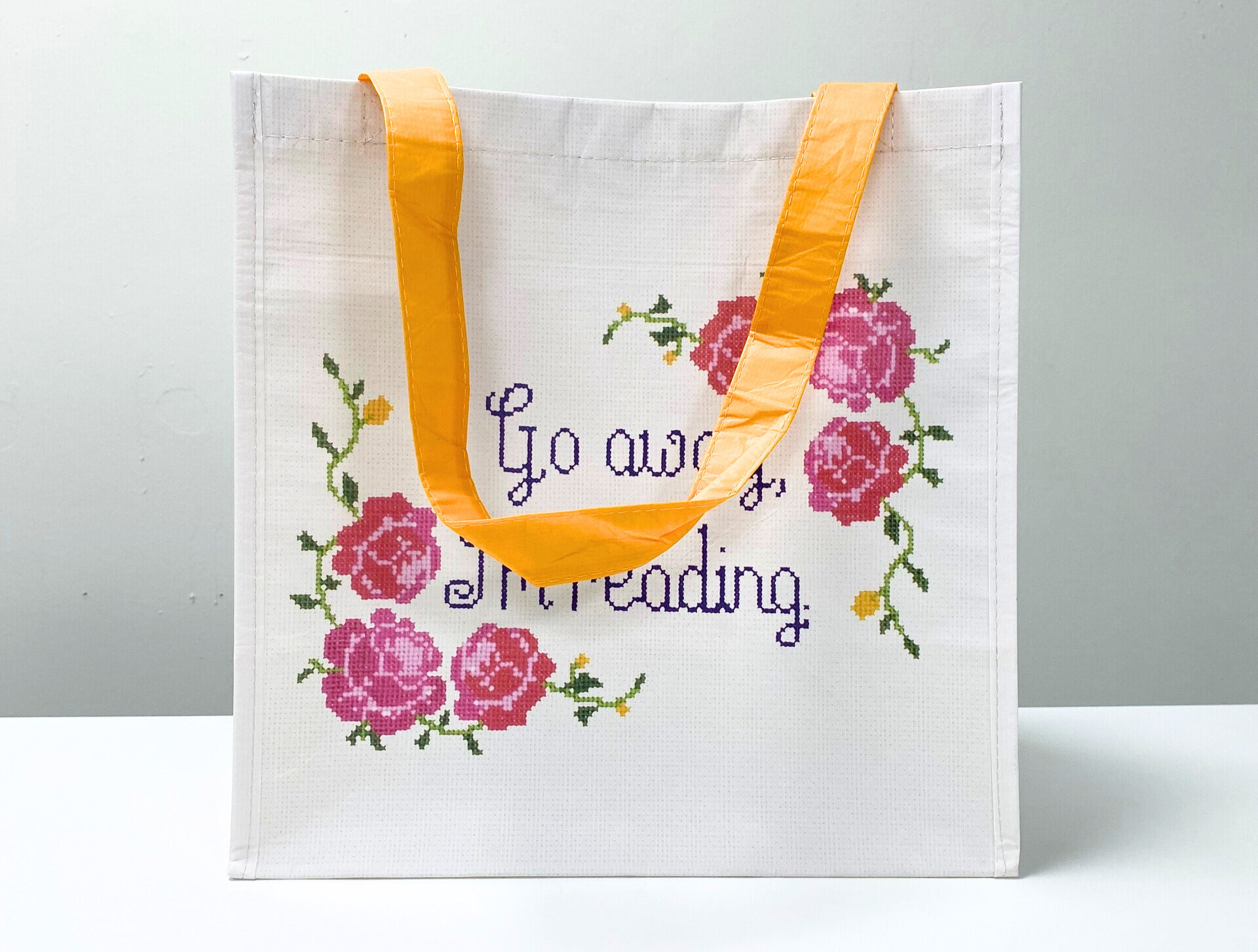

When you prioritize quality instead of focusing solely on price, you tend to receive bags with a defect rate under 2–3 percent, stronger durability, and up to 30–50 percent longer lifespan. This gives your customers a better experience and increases the chances that they will reuse the bag many times, which quietly boosts your brand visibility without any additional advertising cost.

Working with a supplier that maintains proper standards also helps you avoid hidden expenses such as replacing defective goods, rushing urgent shipments, or dealing with customer complaints. Your sourcing process becomes smoother, more predictable, and much kinder to your brand reputation.

To make sure you get the quality you expect, you can always request product samples before placing a large order. And if possible, visiting the factory in person gives you a clearer view of their production process and how seriously they handle quality control. These small steps often bring meaningful long-term rewards for your brand.

When you take the time to define the intended use, everything becomes smoother. Choosing the right GSM, size, handle style, and stitching method ensures that the bag performs exactly as needed. A well-matched design can reduce product failures significantly and make your customers feel that you understand their needs. This creates a more pleasant user experience and increases the chances that your bags will be used again, giving your brand more visibility.

Clear specifications also help your supplier work better for you. When they know the weight of your products, your typical bag dimensions, and your preferred structure, they can recommend the most reliable combination of materials and reinforcements. This prevents guesswork, reduces waste, and saves you from unnecessary reorders.

If you want extra reassurance, you can request a sample based on your actual use case. Testing a prototype with your products gives you confidence that the final order will meet expectations and helps your supplier fine-tune any details before mass production begins.

Match your bag specs to real use to avoid failures and protect your brand.

Match your bag specs to real use to avoid failures and protect your brand.

When you consider the full financial picture instead of only the unit cost, you give yourself far better control over your budget. Factoring in packaging, compliance testing, freight options, and exchange rate fluctuations helps you avoid last-minute expenses and keeps your sourcing predictable. This clarity often saves you a meaningful portion of your budget, sometimes equivalent to 5 to 12 percent of your total order value.

A supplier who is transparent about these details can make a noticeable difference for you. When they outline setup fees, sampling charges, logistics costs, and potential extras from the start, you can compare quotations fairly and identify the partner that truly delivers the best value rather than the lowest number on paper.

To protect your budget even further, you can request a fully itemized quotation before confirming any order. Seeing everything upfront helps you calculate the actual total cost of ownership and prevents unexpected overspending, giving your business a smoother, more predictable sourcing experience.

Working with a supplier who communicates well creates a completely different experience for you. Clear timelines and quick feedback reduce misunderstandings and keep production on track. Reliable manufacturers also maintain steadier quality, helping lower defect rates from the usual 5 to 8 percent down to around 2 to 3 percent.

Strong communication also gives you more control. When a supplier updates you at key stages and flags issues early, your inventory planning and marketing schedules stay stable. This saves you both time and stress during busy seasons.

If you want additional assurance before partnering, you can ask for customer references, request production videos, or visit the factory when possible. These simple steps help you understand how they operate and give you confidence that you are choosing a partner who supports your goals.

Reliable suppliers keep your orders on time and your costs under control.

Reliable suppliers keep your orders on time and your costs under control.

When you give yourself enough time to plan, everything becomes smoother. Setting a clear production timeline, adding a small buffer for unexpected issues, and staying updated throughout the process helps you stay in control. Brands that manage lead time well often avoid unnecessary stress and keep product launches running on schedule.

Working with a manufacturer that provides transparent scheduling also brings peace of mind. When they share progress updates and notify you early about potential delays, you have time to adjust your plans or modify your shipment if needed. This proactive communication helps you protect both your timeline and your margins.

If you want added reassurance, you can request a detailed timeline before production and ask the factory to share photos or videos at key checkpoints. These simple steps help you maintain visibility and ensure your supply chain stays steady.

When you take quality control seriously, the results speak for themselves. Approving artwork before production, checking color accuracy, and reviewing a pre-production sample help ensure that your final bags look exactly the way you imagined. Clean printing, strong seams, and consistent materials make your customers feel more confident in your brand and increase the chances that your bags will be reused.

A manufacturer with a structured quality process also brings more stability to your orders. When they perform checks at different stages of production and share updates with you, you can trust that any issue will be caught early rather than discovered after thousands of pieces have been produced. This saves you both time and replacement costs.

If you want extra peace of mind, you can request a sample from the actual batch or ask for photos and videos during production. These small steps give you better control over branding accuracy and help you deliver a product that truly reflects your standards.

Brands that diversify their supplier base usually enjoy a much steadier flow of goods. Having at least two reliable options gives you backup capacity, more flexibility with lead times, and the ability to compare quality or pricing whenever needed. This extra stability helps your team plan confidently for seasonal peaks or new product launches.

A strong, long-term relationship with your manufacturer also adds meaningful value. When a supplier understands your quality expectations and timelines, they tend to prioritize your orders, flag issues early, and offer better support during production. This makes the entire process smoother for you and reduces the everyday operational pressure on your team.

If you want more certainty, you can maintain light communication with secondary suppliers or keep samples from previous factories. This ensures you always have alternatives ready, giving your business greater resilience and protection against sudden supply chain risks.

Conclusion

Selecting the right shopping bag supplier can shape the quality of your packaging, the reliability of your operations, and the way customers perceive your brand. By avoiding the seven common mistakes outlined in this guide, you give yourself a stronger foundation for consistent quality, fewer production issues, and a more predictable sourcing experience.

A supplier who understands your specifications, communicates clearly, maintains stable quality control, and provides transparent pricing will support your business far better than the lowest-cost option. With the right partner, you can reduce defects, prevent hidden costs, and deliver bags that your customers enjoy using and reusing – helping your brand stand out in a crowded market.

Taking the time to request samples, verify capabilities, and compare suppliers thoughtfully will reward you with a smoother supply chain and long-term confidence in every order you place.

Get Your Company’s Free Sample Delivered to You

Experience K-Packing’s quality before you order. Contact our team to discuss your shopping bag requirements and receive a free sample delivered directly to your address.

Phone: (+84) 855 555 751

Email: info@k-packings.com | sale@k-packings.com

Address:

VIETNAM: 169 Nguyen Ngoc Vu Street, Cau Giay District, Hanoi

ANGOLA: Av. Pedro de Castro Van-Dúnem Loy, Luanda

USA: 7319 N. Loop 1604 E, San Antonio, TX 78233.

In this article, the 7 most common mistakes made during the supplier selection process are outlined, along with how avoiding them can bring long-term benefits to your brand, your operations, and your budget.

Table of Contents

Many businesses, including yours, are often drawn to the lowest-priced supplier. However, when prices are pushed too low, manufacturers usually cut corners by reducing fabric GSM, simplifying stitching, or using lower-grade inks. These compromises don’t show up on the quotation, but they become obvious in the final product: bags tear easily, lose their shape, and leave your customers with a poor impression of your brand.When you prioritize quality instead of focusing solely on price, you tend to receive bags with a defect rate under 2–3 percent, stronger durability, and up to 30–50 percent longer lifespan. This gives your customers a better experience and increases the chances that they will reuse the bag many times, which quietly boosts your brand visibility without any additional advertising cost.

Working with a supplier that maintains proper standards also helps you avoid hidden expenses such as replacing defective goods, rushing urgent shipments, or dealing with customer complaints. Your sourcing process becomes smoother, more predictable, and much kinder to your brand reputation.

To make sure you get the quality you expect, you can always request product samples before placing a large order. And if possible, visiting the factory in person gives you a clearer view of their production process and how seriously they handle quality control. These small steps often bring meaningful long-term rewards for your brand.

Another common issue is choosing a generic bag without matching its specifications to how it will actually be used. A lightweight promotional bag may look fine on paper, but it quickly becomes a problem if your customers need to carry groceries, clothing, or heavier retail items. When the material strength, size, or handle construction doesn’t fit the purpose, the bag fails sooner than expected and reflects poorly on your brand.When you take the time to define the intended use, everything becomes smoother. Choosing the right GSM, size, handle style, and stitching method ensures that the bag performs exactly as needed. A well-matched design can reduce product failures significantly and make your customers feel that you understand their needs. This creates a more pleasant user experience and increases the chances that your bags will be used again, giving your brand more visibility.

Clear specifications also help your supplier work better for you. When they know the weight of your products, your typical bag dimensions, and your preferred structure, they can recommend the most reliable combination of materials and reinforcements. This prevents guesswork, reduces waste, and saves you from unnecessary reorders.

If you want extra reassurance, you can request a sample based on your actual use case. Testing a prototype with your products gives you confidence that the final order will meet expectations and helps your supplier fine-tune any details before mass production begins.

Many buyers focus mainly on the unit price and unintentionally overlook the extra costs that accumulate throughout the sourcing process. These include rework, defect-related losses, import duties, storage fees, sampling charges, and even emergency shipping when schedules slip. Individually, each cost seems manageable, but together they can quietly increase your real spending by 10 to 25 percent, turning what looked like a “cheap deal” into a surprisingly costly one.When you consider the full financial picture instead of only the unit cost, you give yourself far better control over your budget. Factoring in packaging, compliance testing, freight options, and exchange rate fluctuations helps you avoid last-minute expenses and keeps your sourcing predictable. This clarity often saves you a meaningful portion of your budget, sometimes equivalent to 5 to 12 percent of your total order value.

A supplier who is transparent about these details can make a noticeable difference for you. When they outline setup fees, sampling charges, logistics costs, and potential extras from the start, you can compare quotations fairly and identify the partner that truly delivers the best value rather than the lowest number on paper.

To protect your budget even further, you can request a fully itemized quotation before confirming any order. Seeing everything upfront helps you calculate the actual total cost of ownership and prevents unexpected overspending, giving your business a smoother, more predictable sourcing experience.

Many issues arise simply because the supplier’s reliability or communication wasn’t checked beforehand. Slow responses, unclear updates, or sudden changes in production can disrupt your plans and sometimes add 10 to 20 percent in extra costs due to delays or urgent shipments.Working with a supplier who communicates well creates a completely different experience for you. Clear timelines and quick feedback reduce misunderstandings and keep production on track. Reliable manufacturers also maintain steadier quality, helping lower defect rates from the usual 5 to 8 percent down to around 2 to 3 percent.

Strong communication also gives you more control. When a supplier updates you at key stages and flags issues early, your inventory planning and marketing schedules stay stable. This saves you both time and stress during busy seasons.

If you want additional assurance before partnering, you can ask for customer references, request production videos, or visit the factory when possible. These simple steps help you understand how they operate and give you confidence that you are choosing a partner who supports your goals.

Many sourcing issues begin simply because the required lead time was underestimated. Custom bags involve multiple steps such as material preparation, printing, stitching, and inspection, so delays of a few days or even a week are common during busy seasons. These setbacks can disrupt your sales plans or marketing campaigns, and in some cases increase your logistics cost by 10 to 15 percent if urgent shipping becomes necessary.When you give yourself enough time to plan, everything becomes smoother. Setting a clear production timeline, adding a small buffer for unexpected issues, and staying updated throughout the process helps you stay in control. Brands that manage lead time well often avoid unnecessary stress and keep product launches running on schedule.

Working with a manufacturer that provides transparent scheduling also brings peace of mind. When they share progress updates and notify you early about potential delays, you have time to adjust your plans or modify your shipment if needed. This proactive communication helps you protect both your timeline and your margins.

If you want added reassurance, you can request a detailed timeline before production and ask the factory to share photos or videos at key checkpoints. These simple steps help you maintain visibility and ensure your supply chain stays steady.

Quality issues often appear when proper checks are skipped. Without reviewing print proofs, testing colors, or inspecting early samples, you may end up with bags that have misaligned artwork, faded tones, or weak stitching. These small errors can make your brand look less professional than it deserves. In some cases, inconsistent printing or structural defects can affect as much as 5 percent of a shipment, creating frustration for both your team and your customers.When you take quality control seriously, the results speak for themselves. Approving artwork before production, checking color accuracy, and reviewing a pre-production sample help ensure that your final bags look exactly the way you imagined. Clean printing, strong seams, and consistent materials make your customers feel more confident in your brand and increase the chances that your bags will be reused.

A manufacturer with a structured quality process also brings more stability to your orders. When they perform checks at different stages of production and share updates with you, you can trust that any issue will be caught early rather than discovered after thousands of pieces have been produced. This saves you both time and replacement costs.

If you want extra peace of mind, you can request a sample from the actual batch or ask for photos and videos during production. These small steps give you better control over branding accuracy and help you deliver a product that truly reflects your standards.

Relying on just one supplier can leave your entire sourcing process vulnerable. If that factory faces a production pause, material shortage, or sudden capacity limit, your timeline can be pushed back unexpectedly. Even a short disruption can impact your stock levels and, in some cases, raise your overall sourcing cost by a noticeable margin due to rush orders or last-minute changes.Brands that diversify their supplier base usually enjoy a much steadier flow of goods. Having at least two reliable options gives you backup capacity, more flexibility with lead times, and the ability to compare quality or pricing whenever needed. This extra stability helps your team plan confidently for seasonal peaks or new product launches.

A strong, long-term relationship with your manufacturer also adds meaningful value. When a supplier understands your quality expectations and timelines, they tend to prioritize your orders, flag issues early, and offer better support during production. This makes the entire process smoother for you and reduces the everyday operational pressure on your team.

If you want more certainty, you can maintain light communication with secondary suppliers or keep samples from previous factories. This ensures you always have alternatives ready, giving your business greater resilience and protection against sudden supply chain risks.

Conclusion

Selecting the right shopping bag supplier can shape the quality of your packaging, the reliability of your operations, and the way customers perceive your brand. By avoiding the seven common mistakes outlined in this guide, you give yourself a stronger foundation for consistent quality, fewer production issues, and a more predictable sourcing experience.

A supplier who understands your specifications, communicates clearly, maintains stable quality control, and provides transparent pricing will support your business far better than the lowest-cost option. With the right partner, you can reduce defects, prevent hidden costs, and deliver bags that your customers enjoy using and reusing – helping your brand stand out in a crowded market.

Taking the time to request samples, verify capabilities, and compare suppliers thoughtfully will reward you with a smoother supply chain and long-term confidence in every order you place.

Get Your Company’s Free Sample Delivered to You

Experience K-Packing’s quality before you order. Contact our team to discuss your shopping bag requirements and receive a free sample delivered directly to your address.

Phone: (+84) 855 555 751

Email: info@k-packings.com | sale@k-packings.com

Address:

VIETNAM: 169 Nguyen Ngoc Vu Street, Cau Giay District, Hanoi

ANGOLA: Av. Pedro de Castro Van-Dúnem Loy, Luanda

USA: 7319 N. Loop 1604 E, San Antonio, TX 78233.